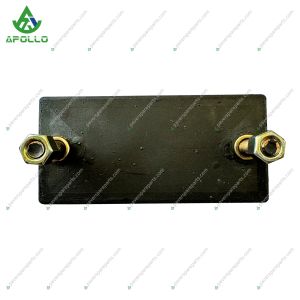

The APOLLO Track Pads, complete with their accompanying bolts and

nuts for the BF300C Asphalt Paver, represent a critical

ground-engagement system where brute-force machinery meets the

delicate art of precision road construction. This assembly is not

merely a set of wear parts; it is the foundational interface

between the paver's immense weight and the vulnerable,

high-temperature asphalt mat. Its performance dictates the quality

of the final road surface, the efficiency of the paving operation,

and the long-term mechanical health of the paver itself.

The BF300C Asphalt Paver is a machine designed for a singular,

critical purpose: to lay a smooth, uniform, and perfectly

consistent layer of asphalt. Any deviation in this process results

in a compromised road surface prone to premature wear. The track

pads, also known as track shoes, are the large, flat plates that

form the continuous belt of the paver's tracks. Their primary and

most vital function is to provide exceptional flotation. By

distributing the machine's substantial weight over a large surface

area, they achieve a low ground pressure. This prevents the paver

from sinking into or rutting the soft, hot asphalt. Without this

carefully engineered flotation, the tracks would leave permanent

deformations in the mat, imperfections that the following rollers

cannot erase, thereby ruining the smoothness and structural

integrity of the pavement.

The inclusion of "APOLLO" as the brand signifies an expectation of

resilience and durability. The operating environment for these

components is exceptionally punishing. They are subjected to

relentless abrasion from the aggregate mix, intense and constant

heat from the asphalt that can anneal and weaken inferior metals,

and the tremendous internal stresses of steering and maneuvering.

APOLLO Track Pads are manufactured to resist this degradation,

maintaining their shape and strength to ensure consistent

performance. However, their durability is intrinsically linked to

the specified "Bolts and Nuts." These fasteners are not generic

hardware; they are high-strength, heat-treated components

engineered to withstand shear forces and vibrational loosening. A

loose track pad is a catastrophic risk, potentially causing severe

damage to the undercarriage and posing a safety hazard. The

integrity of the entire system relies on the unwavering grip of

these specialized bolts and nuts.

Furthermore, the designation for the BF300C model indicates a

tailored engineering solution. The geometry of the pad, its weight,

and the specific bolt pattern are all optimized for the BF300C's

weight distribution and dynamic operation. This ensures balanced

tracking, smooth transitions, and stable power transfer from the

paver's drivetrain to the ground. Stability is the precursor to

precision; a stable paver ensures that the screed—the component

that shapes and pre-compacts the asphalt—can operate without jerks

or dips, laying down a perfectly consistent mat.

In essence, the APOLLO Track Pad assembly for the BF300C is a

consumable system of strategic importance. It functions as a

protective shield, simultaneously safeguarding the delicate asphalt

surface from the machine's weight and protecting the paver's

undercarriage from the harsh job site. The pads, bolts, and nuts

work in unison as an indispensable partner in quality road

construction, ensuring that the machine's movement is an asset to

the process, not a liability. Their silent, relentless work under

the machine is what ultimately paves the way for a flawless,

long-lasting road.