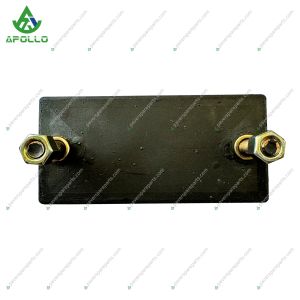

High Quality APOLLO Rubber Track Pad Shoes For Asphalt Paver S700

PN 2390756

The APOLLO Rubber Track Pad Shoes for Asphalt Paver S700 (PN 2390756) represent a specialized solution designed to enhance the

functionality and longevity of asphalt paving equipment. These

track pad shoes serve as critical components that directly impact

machine performance, surface finish quality, and operational

efficiency during paving projects.

Functional Design and Purpose

Rubber track pad shoes are engineered as an alternative to

conventional steel track systems, offering distinct advantages for

asphalt applications. The APOLLO Rubber Track Pad Shoes are specifically configured for compatibility with the S700 asphalt paver model, providing a precise fit that maintains equipment integrity while

delivering superior operational characteristics.

Material Composition and Engineering

Manufactured from premium-grade rubber compounds, these track shoes

demonstrate exceptional resistance to:

- Thermal stress from hot asphalt surfaces

- Abrasive wear from continuous pavement contact

- Environmental factors including UV exposure and chemical

interactions

The material formulation ensures consistent performance across

varying temperature ranges while maintaining flexibility to absorb

operational stresses.

Operational Advantages

1. Enhanced Traction Control

The engineered tread pattern optimizes grip across different paving

surfaces, including:

- Fresh asphalt mats

- Existing pavement surfaces

- Transitional areas between substrates

This traction stability minimizes slippage during operation while

allowing for precise machine positioning.

2. Vibration Dampening

The inherent shock-absorbing properties of the rubber material

reduce equipment vibrations transmitted to both the machine frame

and operator platform, contributing to:

- Improved operator comfort during extended shifts

- Reduced mechanical stress on paver components

- Lower noise emissions in sensitive work environments

3. Weight Distribution Efficiency

The design promotes even load distribution across the track

surface, preventing concentrated ground pressure that could

compromise:

- Subgrade integrity beneath fresh asphalt

- Surface finish uniformity

- Base material displacement

Application Scenarios

These track pad shoes are ideally suited for:

- Highway and arterial road construction

- Municipal street paving and rehabilitation

- Commercial parking area development

- Airport runway resurfacing projects

- Precision paving operations requiring superior surface finishes

Maintenance and Service Life Considerations

Proper care and inspection protocols can significantly extend the

functional lifespan of these components:

- Regular cleaning to remove asphalt buildup and debris

- Periodic inspection for signs of:

- Surface cracking or dry rot

- Tread pattern wear

- Structural deformation

- Timely replacement before excessive wear compromises performance

The durable rubber formulation ensures these components outlast

standard rubber track shoes, providing cost efficiency through

reduced replacement frequency.

Installation and Compatibility

The PN 2390756 designation ensures proper fitment with the specified paver model

without requiring modifications. The replacement process follows

standard procedures, allowing for:

- Minimal equipment downtime during changeouts

- Consistent performance matching OEM specifications

- Reliable operation throughout the service interval

Economic and Operational Benefits

The use of these high-quality track shoes translates to measurable

project advantages:

- Reduced surface repair requirements from track marks

- Lower maintenance costs from decreased equipment vibration damage

- Improved fuel efficiency through optimized traction

- Enhanced productivity from consistent machine performance

| Product Name | Track pad |

| MOQ | 1pc |

| Applied to | Asphalt paver |

| Condition | 100% New |

| Brand | APOLLO |

| Installed on | Track chain |

| Usage | Undercarriage system |

| Quality | High |